The energy industry encompasses a range of sectors including wind power, hydroelectric power, and oil and gas extraction. Each sector has unique demands for braking systems that ensure safety, reliability, and efficiency.

Wind Power

Application Scenarios

Offshore wind turbines

Onshore wind turbines

Wind Turbine Brakes: Specifically designed for both onshore and offshore wind turbines, these brakes provide efficient and reliable braking and stopping control to ensure the safety of turbines under varying wind conditions.

Yaw Brakes: Used to control the yaw mechanism of wind turbines, these brakes provide precise control to optimize the turbine’s position relative to wind direction.

Pitch Brakes: For controlling the pitch of the turbine blades, these brakes ensure that the blades are positioned correctly to maximize energy capture and protect against excessive wind speeds.

Corrosion-resistant Brakes: Utilizing anti-corrosion materials and coatings to withstand harsh environmental conditions, especially for offshore installations, thereby extending the service life of the brakes.

Hydroelectric Power

Application Scenarios

Hydroelectric generators

Turbine control systems

Solutions

Hydraulic Brakes: Provide reliable braking force for hydroelectric generators, ensuring precise control during maintenance and emergency stops.

High-torque Brakes: Suitable for large-scale hydroelectric turbines, offering robust braking performance to handle the high rotational inertia.

Emergency Braking Systems: Provide quick and effective braking in emergency situations, ensuring the safety and protection of both equipment and personnel.

Environmental-resistant Brakes: Designed to operate in the moist and potentially corrosive environment of hydroelectric power plants, ensuring long-term reliability and low maintenance.

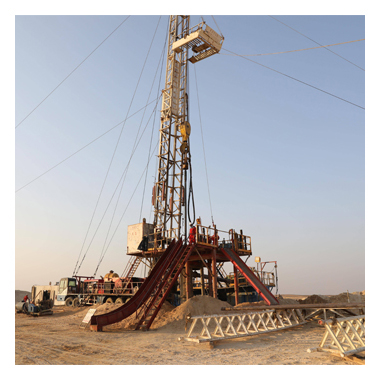

Oil and Gas Extraction

Application Scenarios

Drilling rigs

Offshore platforms

Pumping stations

Solutions

Explosion-proof Brakes: Essential for use in hazardous environments where flammable gases may be present, ensuring safety and compliance with industry standards.

High-torque Hydraulic Brakes: Used in drilling rigs and other heavy machinery, providing the necessary braking force to handle high loads and operational stresses.

Emergency Braking Systems: Critical for ensuring the safety of drilling operations, these systems provide rapid and reliable braking in emergency situations.

Subsea Brakes: Designed for use in underwater applications, such as subsea drilling equipment, providing reliable braking performance in deep-sea environments.

Conclusion

Providing tailored braking solutions for the energy industry requires a deep understanding of the specific demands and environmental conditions of each sector. By offering efficient, reliable, and durable braking systems, we can ensure the safety and stability of various energy installations, supporting the industry’s goal of reliable and sustainable energy production. Comprehensive after-sales services further enhance the long-term reliability and performance of these critical systems.

Implementation Steps

Communicate thoroughly with clients to understand specific application scenarios and braking requirements.

Assess environmental conditions, such as seawater corrosion, high humidity, and high salinity.

Design suitable braking systems based on the needs and environmental conditions.

Determine materials, braking methods, and control systems.

Manufacture the brakes according to the design plan, ensuring quality and performance.

Conduct rigorous testing under actual use environments to ensure the reliability and safety of the braking system.

Ensure the system operates normally and provide necessary technical support.

Provide regular maintenance and upkeep services to ensure long-term stable operation of the braking system.

Respond promptly to client repair and replacement needs, offering technical support and training.

Please submit the product requirements and we will contact you immediately