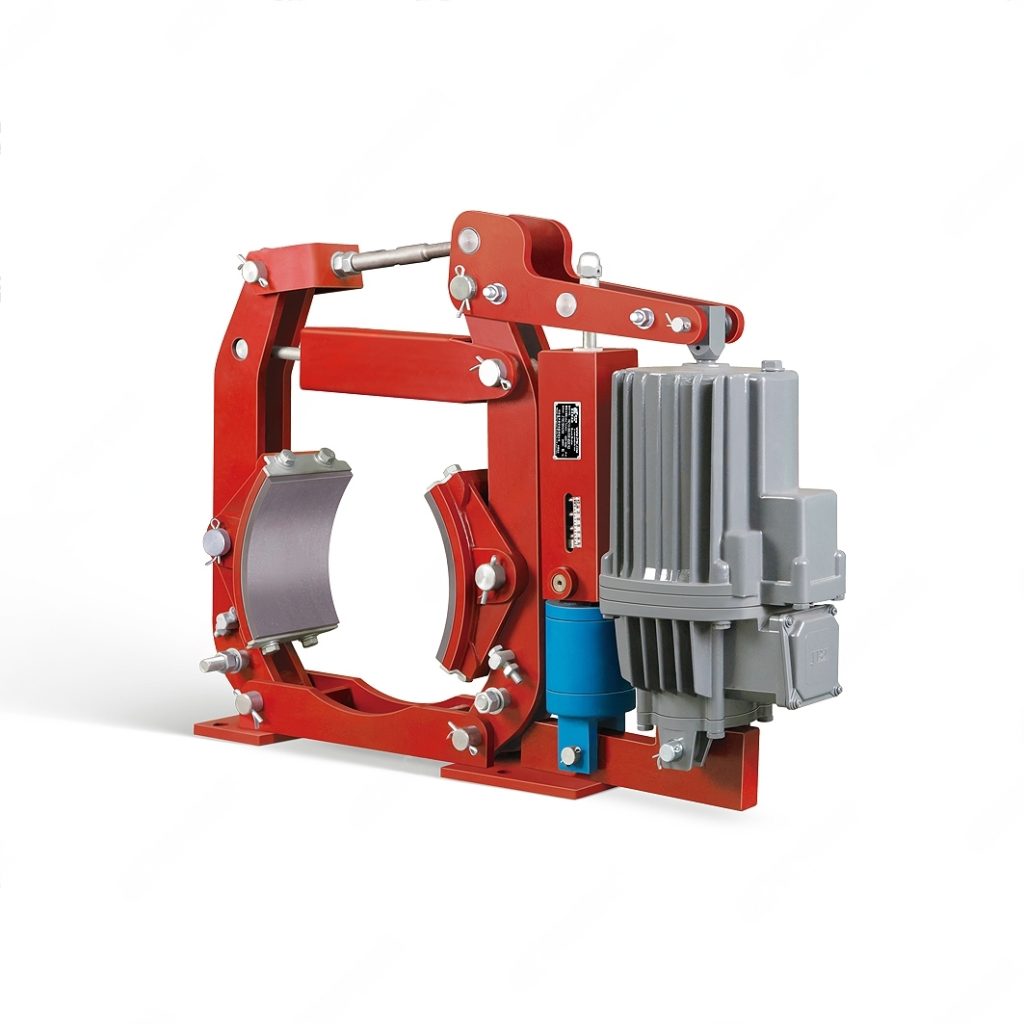

Two-step, Delayed electro-hydraulic drum brakes can be extensively used on large/middle outdoor cranes, having excellent deceleration braking and storm braking performance. It can also be used on large and middle special cranes,realizing stable deceleration braking and maintenance braking. Ideal braking performance of these series products is also represented on Belt transport vehicles.

The YW-E series brake is two-step braking device. In the first braking step, a minor torque(adjustable with the prescribed limits) is exerted to make stable deceleration braking. When body stops, the second step starts. A bigger torque (adjustable with the prescribed limits) is exerted to realize reliable maintenance or storm braking. The interval time between the two steps staring can be adjusted by damping single way throttle in cylinder circuit(with 1-15 seconds).

Standards Compliant:

The dimensions and braking torque parameters of this series brakes comply with JB/T6406-2006,JB/ZQ4388-86 standard(with A series), and DIN15435 standard.

Thrusters equipped on them are ED series thrusters which comply with DIN15430 standard.

Main Feature:

Brake lining is of clamped integral forming structure, which is easy and quick to replace.

Interlocking shoe clearance balancing device (patented technology) and shoe auto-aligning device constantly equalize the clearance of brake shoes on both sides and make adjustment unnecessary, completely avoiding brake lining one side sticking to brake wheel.

Main hinge points are equipped with self-lubricating bearing ,making high efficiency of transmission ,long ser vice life. Lubricating is unnecessary during operation.

Enclosed spring tube protects spring from damage and contamination.

The Ed series thrusters are characterized by flexible action and long operating life.

Brake closes in case of power failure (Fail-Safe Principle).Braking by spring power.Lifting by thruster.

Operating Condition

Ambient temperature:-20°C〜+ 50°C

Relative humidity:≤90%

Voltages: AC 3phase 380V 50Hz (Other voltage can be made as required)

Intermittent (S3-60%.1200times per hour)and continuous (S1)

special requirements can be discussed before production.

Basic Parameter:

Product model: YW-E200, YW-E250, YW-E300, YW-E315, YW-E400

Suitable wheel diameter: 200 ~ 400mm

Braking torque: 200 ~ 2500Nm

Implementation Steps

Communicate thoroughly with clients to understand specific application scenarios and braking requirements.

Assess environmental conditions, such as seawater corrosion, high humidity, and high salinity.

Design suitable braking systems based on the needs and environmental conditions.

Determine materials, braking methods, and control systems.

Manufacture the brakes according to the design plan, ensuring quality and performance.

Conduct rigorous testing under actual use environments to ensure the reliability and safety of the braking system.

Ensure the system operates normally and provide necessary technical support.

Provide regular maintenance and upkeep services to ensure long-term stable operation of the braking system.

Respond promptly to client repair and replacement needs, offering technical support and training.

Please submit the product requirements and we will contact you immediately