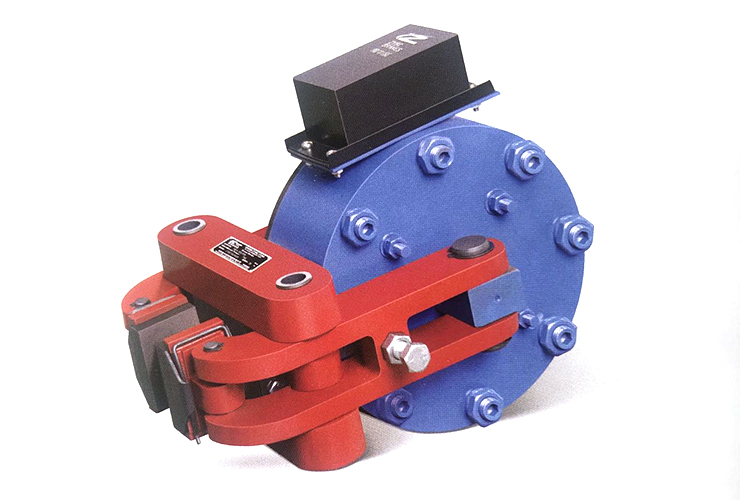

DCPZ Series electromagnetic disc brakes are widely used for speed reducing, stopping or braking of the low or medium torque driving mechanism. The brakes can also be applied as tension brake on winding machines, such as paper-web tension control, news paper publishing tension control, steel unwind control, wire and cable reel unwind tension etc.

Main Features:

▲ Compact structure and small size, light. It is easy to control and operate.

▲Many kind of friction materials can be chosen,it adapts to the different operating modes

▲ With the manual release function,emergency release when the power failure

▲The linings are of inserting installation style and non-asbestos. It is easy to be replaced.

▲Brake closes in case of power failure (Fail-Safe Principle).Normally closed design-Spring Braking, released by electromagnetic

Operating Conditions:

◆Ambient temperature:-20°C〜+ 40°C

◆Relative humidity:≤90%

◆ Voltages: AC 380V 50Hz (Other voltage can be made as required)

◆ Working condition: No risk of explosion conditions, gas and electrical angstrom which will corrode metal and damage the insulation.

◆Special requirements can be discussed before production.

Basic Parameters:

●Product model:DCPZ-250、DCPZ-300、DCPZ-400、

● Applicable disc diameter:ØD≥Ø600mm

●Brake moment:900~2600Nm

Implementation Steps

Communicate thoroughly with clients to understand specific application scenarios and braking requirements.

Assess environmental conditions, such as seawater corrosion, high humidity, and high salinity.

Design suitable braking systems based on the needs and environmental conditions.

Determine materials, braking methods, and control systems.

Manufacture the brakes according to the design plan, ensuring quality and performance.

Conduct rigorous testing under actual use environments to ensure the reliability and safety of the braking system.

Ensure the system operates normally and provide necessary technical support.

Provide regular maintenance and upkeep services to ensure long-term stable operation of the braking system.

Respond promptly to client repair and replacement needs, offering technical support and training.

Please submit the product requirements and we will contact you immediately