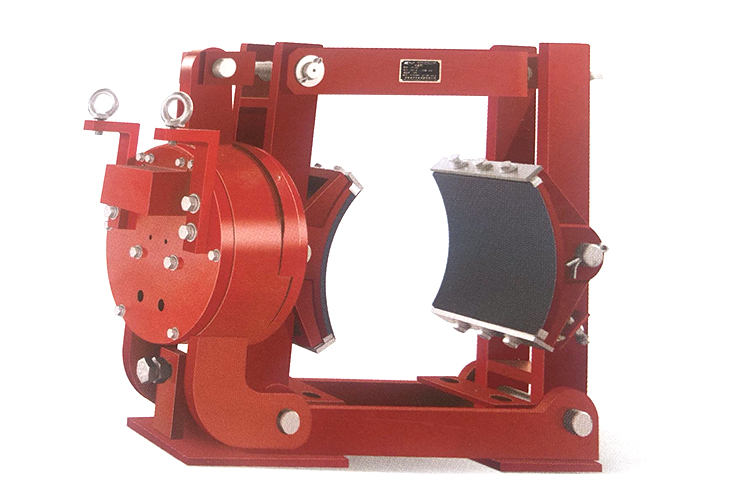

ZWZA, ZWZB Series DC electromagnetic drum brakes can be extensively used for deceleration and stopping of electromagnetic lifter and various lift, belt transport, port handling, metallurgical and building machinery using DC drive or DC net. They are not suitable for machines using AC drive.

This series brakes is mainly used for taking replace of old products of ZWZ series.

Main Features:

▲ Interlocking shoe clearance balancing device (patented technology) and shoe auto-aligning device constantly equalize the clearance of brake shoes on both sides and make adjustment unnecessary, completely avoiding brake lining one side sticking to brake wheel.

▲ Main hinge points are equipped with self-lubricating bearing ,making high efficiency of transmission ,long ser vice life. Lubricating is unnecessary during operation.

▲ Enclosed spring tube protects spring from damage and contamination.

▲ Brake lining is of clamped integral forming structure, which is easy and quick to replace,There are semi-metallic (non asbestos) hard and semi-hard, soft (non asbestos) and other brake pads of different materials for customers to choose

▲ New type armature iron auto-aligning device which can keep armature iron and magnetic yoke jointing well all the time.

▲ Brake closes in case of power failure (Fail-Safe Principle).Braking by spring power.Electromagnetic release.

Operating Conditions:

◆ Ambient temperature:-20°C〜+ 40°C;

◆ Relative humidity:≤90%;

◆ Operating duty: intermittent (S3-25,40,60%.≤720 times per hour)and continuous (S1-100%)

◆ Voltages: DC110V,220V;

◆ Working condition: No risk of explosion conditions, gas and electrical angstrom which will corrode metal and damage the insulation

Basic Parameters:

● Product Model:ZWZA-400、ZWZA-500、ZWZA-600、ZWZA-700、ZWZA-800、ZWZB-400/400、ZWZB-400/500、ZWZB-500/400、ZWZB-500/500、ZWZB-500/600、ZWZB-630/500、ZWZB-630/600、ZWZB-630/700、ZWZB-710/600、ZWZB-710/700、ZWZB-710/800、ZWZB-800/700、ZWZB-800/800

● Applicable Wheel Diameter:400~800mm

● Braking Torque:450~10000Nm

Implementation Steps

Communicate thoroughly with clients to understand specific application scenarios and braking requirements.

Assess environmental conditions, such as seawater corrosion, high humidity, and high salinity.

Design suitable braking systems based on the needs and environmental conditions.

Determine materials, braking methods, and control systems.

Manufacture the brakes according to the design plan, ensuring quality and performance.

Conduct rigorous testing under actual use environments to ensure the reliability and safety of the braking system.

Ensure the system operates normally and provide necessary technical support.

Provide regular maintenance and upkeep services to ensure long-term stable operation of the braking system.

Respond promptly to client repair and replacement needs, offering technical support and training.

Please submit the product requirements and we will contact you immediately