Marine engineering demands highly specialized and rigorous braking solutions, primarily applied to ships, offshore drilling platforms, and port lifting equipment.

Ship Braking Solutions

Application Scenarios:

Commercial vessels

Fishing boats

Yachts

Solutions:

Electromagnetic Brakes: Suitable for the main propulsion systems of ships, providing stable and reliable braking control, ensuring safety during maritime navigation.

Hydraulic Brakes: Used in anchor winches and capstan systems, providing strong braking force to ensure safe mooring and maneuvering of ships.

Corrosion-resistant Brakes: Utilize anti-corrosion materials and special coatings to withstand high salinity and humidity in marine environments, extending the lifespan of the brakes.

Offshore Drilling Platform Braking Solutions

Application Scenarios:

Fixed drilling platforms

Semi-submersible drilling platforms

Jack-up drilling platforms

Solutions:

Explosion-proof Brakes: Provide high-safety braking solutions in flammable and explosive environments, ensuring the safe operation of drilling platforms.

High-torque Brakes: Suitable for drilling equipment and hoisting systems, offering strong braking force to ensure stability under high-load operations.

Emergency Braking Systems: Provide emergency braking functions for critical equipment, responding quickly in case of emergencies to ensure platform and personnel safety.

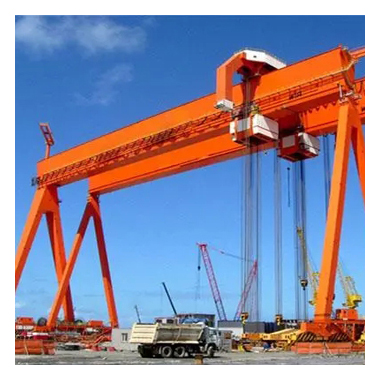

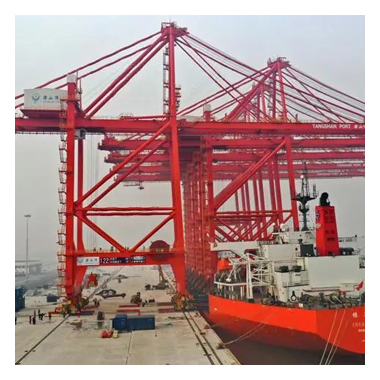

Port Lifting Equipment Braking Solutions

Application Scenarios:

Container cranes

Gantry cranes

Loading bridges

Solutions:

High-efficiency Electromagnetic Brakes: Used in various lifting equipment’s main and auxiliary systems, offering efficient and reliable braking performance.

Heavy-duty Hydraulic Brakes: Suitable for large lifting equipment, providing strong braking force and durability, ensuring safety under heavy-load operations.

Automated Control Braking Systems: Integrate automated control systems to achieve intelligent braking management for lifting equipment, enhancing work efficiency and safety.

Offshore Wind Power Equipment Braking Solutions

Application Scenarios:

Offshore wind turbines

Offshore substations

Solutions:

Wind Turbine Brakes: Specifically designed for offshore wind turbines, providing efficient braking and stopping control to ensure the safety of wind turbines under high wind conditions.

Corrosion-resistant Braking Systems: Suitable for marine environments, using anti-corrosion materials and technology to extend the lifespan of the braking system.

Maintenance-friendly Brakes: Designed with easy-to-maintain and replaceable brake components, reducing the complexity and cost of offshore maintenance.

Conclusion

Industrial brake solutions for marine engineering must consider multiple factors, including environmental conditions, application scenarios, and specific requirements. Providing efficient, reliable, and durable braking systems ensures the safety and stability of various marine equipment while offering comprehensive after-sales services to ensure long-term reliability.

Implementation Steps

Communicate thoroughly with clients to understand specific application scenarios and braking requirements.

Assess environmental conditions, such as seawater corrosion, high humidity, and high salinity.

Design suitable braking systems based on the needs and environmental conditions.

Determine materials, braking methods, and control systems.

Manufacture the brakes according to the design plan, ensuring quality and performance.

Conduct rigorous testing under actual use environments to ensure the reliability and safety of the braking system.

Ensure the system operates normally and provide necessary technical support.

Provide regular maintenance and upkeep services to ensure long-term stable operation of the braking system.

Respond promptly to client repair and replacement needs, offering technical support and training.

Please submit the product requirements and we will contact you immediately